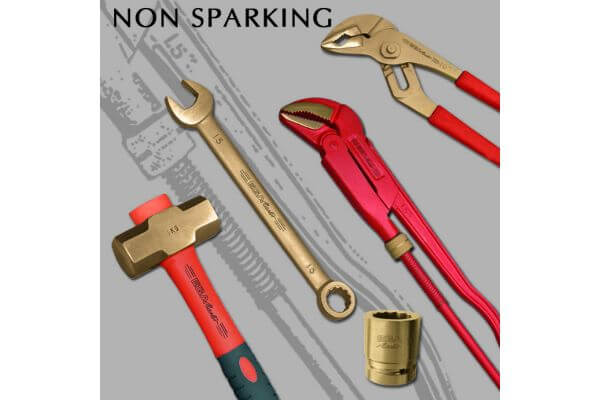

Non-Sparking Tools

Non-Sparking Tools: Characteristics, Safety Advantages, and Utility

Non sparking tools are essential in environments where flammable or explosive materials are present. These tools are designed to prevent sparks from being generated during use, which can be hazardous in such environments. In this article, we will discuss the characteristics of non-sparking tools, the safety advantages of using them, the industrial utility of non-sparking tools, available varieties, tips for using them, and ordering information.

Characteristics of Non-Sparking Tools

Non sparking tools are made of materials that are non-sparking and non-magnetic. The most used materials for non-sparking tools are alloys of brass, bronze or copper-nickel alloy, copper-aluminum, aluminum-bronze, copper-beryllium, or beryllium bronze. These materials do not generate sparks when struck against other metals and are also corrosion resistant. The hand tools manufactured under this category are designed to be used in electrically sensible atmospheres and ATEX zones to prevent potential contact spark. When working in hazardous zones, the international workplace safety standards require the use of non-sparking tools. These regulations are set to prevent explosions in presence of flammable gasses, or release of electricity through arc flash in live workplaces.

Safety Advantages of Non-Sparking Tools

- Reduced Fire Hazard: Non sparking tools prevent sparks from being generated, reducing the risk of fire hazards.

- Safe in Hazardous Environments: Non sparking tools are essential in environments where flammable or explosive materials are present.

- Increased Worker Safety: Using non sparking tools helps to ensure the safety of workers, reducing the risk of accidents and injuries.

Industrial Utility of Non-Sparking Tools

Non sparking tools are used in various industrial applications, including:

- Oil and Gas Industry: Non sparking tools are widely used in the oil and gas industry, where flammable materials are commonly present.

- Chemical Industry: Non sparking tools are used in the chemical industry, where the risk of fire and explosion is high.

- Mining Industry: Non sparking tools are used in the mining industry, where flammable gases are commonly present.

Technical Highlights of “non-sparking” Tools

Low Tensile Strength – The “non-sparking” metals present a low tensile strength when compared to those that are prone to spark such as steel and iron. The lower tensile strength has less possibility of creating a spark. The non-static metals’ low resistance however presents a lower stretch against tearing. Hence the life cycle of these tools is relatively lower than those made of steel or iron alloys- which are a relatively low price to be paid for spark-free safety in sensitive hazardous zones.

Presence of cold sparks – Although non-sparking tools offer great safety, there is still a fraction of sparks that exist. These are called “cold sparks” and present a very low ignition substance in the world of metals. Therefore, a “non-sparking” tool features a significantly lower risk of creating a spark; they do not eliminate the possibility of sparks.

Non-metallic spark-free tools – For minimizing the existence of cold sparks, Non-metals substances such as wood, leather, and plastic are integrated with tools. We even offer equipment such as scrapers or scoops that are a hundred percent metallic and present zero friction spark hazard.

Fire Ignition Protection – The main purpose of the non-sparking tools is the prevention of ignition of fire in hazardous workplaces- whether there is a significant presence of flammable gasses, vapours, docs, and liquids.

Why You Need Non-Sparking Tools and Tips for Appropriate Use:

- Follow the guidelines proved immensely beneficial; to reduce the ignition risk.

- Store all the “non-sparking” tools clean and free from contaminants such as ferrous particles.

- Choose the appropriate tool size to help correct fitting and prevents slipping that can cause ignition by surface friction.

- Avoid using non-sparking hand tools in contact or presence of solvents, such as acetylene.

- Performing these tasks in presence of local or mechanical ventilation systems reduces the potential hazards.

- Routine redressing of your non-sparking tools and use of these tools with appropriate personal protection equipment.

Order Today

Non sparking tools are an essential component of many industrial applications, providing protection against the hazards associated with flammable or explosive materials. These tools offer several safety advantages, reducing the risk of fire hazards, and increasing worker safety. By ordering your non sparking tools today, you can ensure the safety and efficiency of your industrial operations.