Masto

Wire Rope Lubrication: The Ultimate Solution with Masto

Wire ropes are commonly used in heavy-duty industries, such as offshore oil and gas rigs, cargo and shipping, marine industries, and public bridges. Wire ropes require regular maintenance, including lubrication, to prevent corrosion, extend their lifespan, and ensure safe operation. Lubricating wire ropes is crucial to avoid mid-operation incidents, wire rope fatigue, and tensile-related failure. This article examines the importance of wire rope lubrication, the characteristics affecting wire rope degeneration, and how Masto’s lubrication solution can help.

Advantages of Masto

- Prolonging the lifespan of wire ropes

- Improving functionality

- Reducing maintenance costs

- Easy to use

- List Item

- Compatible with dry and wet materials

- Penetrating the core of the wire

- Lubricating steel ropes, galvanized varieties, or other materials

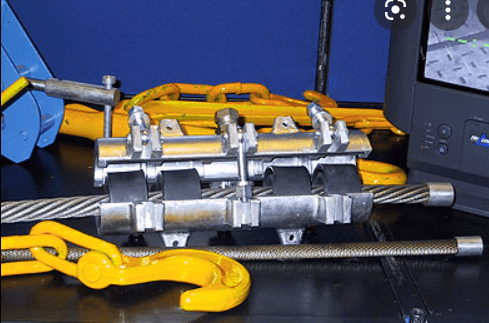

Masto’s lubrication solution is designed for easy administration and can be used to lubricate wire ropes under pressure. The lubrication process is carried out by using split seals, which create a high-pressure environment for lubrication. These seals are engineered with two halves that come together and are further secured with two chains. A pump administers the lubricating content while the wire rope roller continues reeling the rope through the chamber. The systematic application of Masto’s lubricators creates a minimum of 285 PSI, the lowest amount of pressure required in the lubrication chamber, to gain a complete lubricating result. Despite the material of the rope, the mechanical wear, and moisture in an environment, the wires are prolonged significantly after Masto wire lubricators reduce friction, increase functionality, and prolong the wires’ lifespan.

Wire rope lubrication is a critical maintenance task that helps to prevent wire rope failure due to environmental degeneration, such as rusting and high tensile stress. Regular wire rope lubrication can extend the lifespan of wire ropes, reducing maintenance costs and improving functionality.

Wire rope degeneration can be affected by various factors, including overburdening the load limit, cyclic loading (bending, tension, and torsion), rate of periodic lubrication, abrasive factors, the wire rope component’s design, weathering, and corrosive material exposure. When wire rope degeneration is severe enough, the rope can fail by single or multiple raptures in the structure. These failures can occur mid-operation while handling a load, posing a significant risk to personnel and equipment. To avoid such circumstances, two factors play a crucial role: routine inspection of wires and appropriate lubrication.

Wire rope lubrication is a critical maintenance task that helps to prevent wire rope failure, extend its lifespan, and ensure safe operation. Masto’s lubrication solution offers an effective and comprehensive solution for lubricating wire ropes, penetrating both the top layers and inside of wire ropes for corrosion-free and water-resistant characteristics. Masto’s lubrication solution is easy to use, compatible with dry and wet materials, and can be applied to various wire ropes and sheathed umbilical cables with different structural designs. Using Masto’s lubrication solution, wire ropes can last considerably longer, lowering maintenance costs and improving functionality.

Lubrication Solution by Masto

Masto is an international elite brand that provides an effective wire rope lubrication solution that can be applied to a variety of wire ropes and steel-sheathed umbilical cables with different structural designs. Masto’s Original Wire Rope Lubricator was made in Norway. It was invented as the first effective wire rope lubricator worldwide to address an in-house incident due to rusting and lack of lubrication. Masto’s lubricator is designed to be compatible with dry and wet materials, penetrate the core of the wire, and lubricate steel ropes, galvanized varieties, or other materials.

Masto’s lubrication solution is different from many other brands that offer only cable greaser. Such mixtures of greases are known to lubricate only the top surface of wire ropes, leaving the core vulnerable to rustication and breakage due to imposed tension by loads. On the other hand, Masto’s lubricator uses a combination of grease and additives for a thorough lubrication process that covers both the top layers and inside of wire ropes, offering corrosion-free and water-resistant characteristics.

CONTACT US TODAY

If you’re looking for a perfect wire rope lubrication solution, there’s no better choice than Masto lubricators in the market. Get yours today.